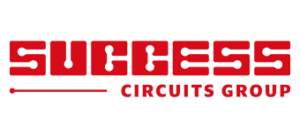

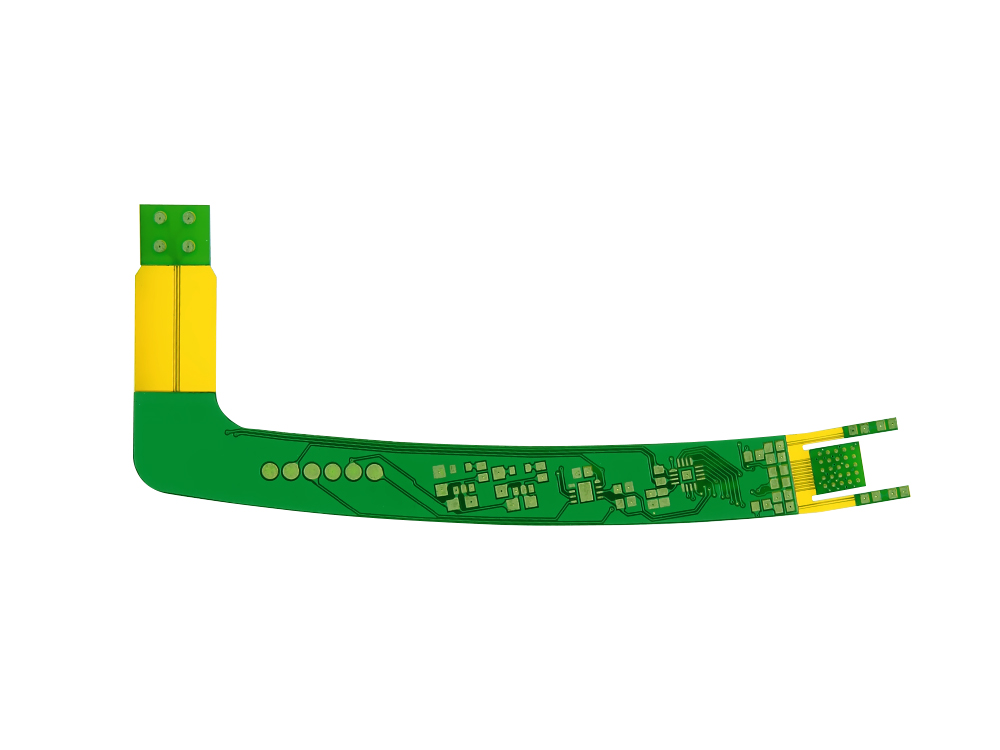

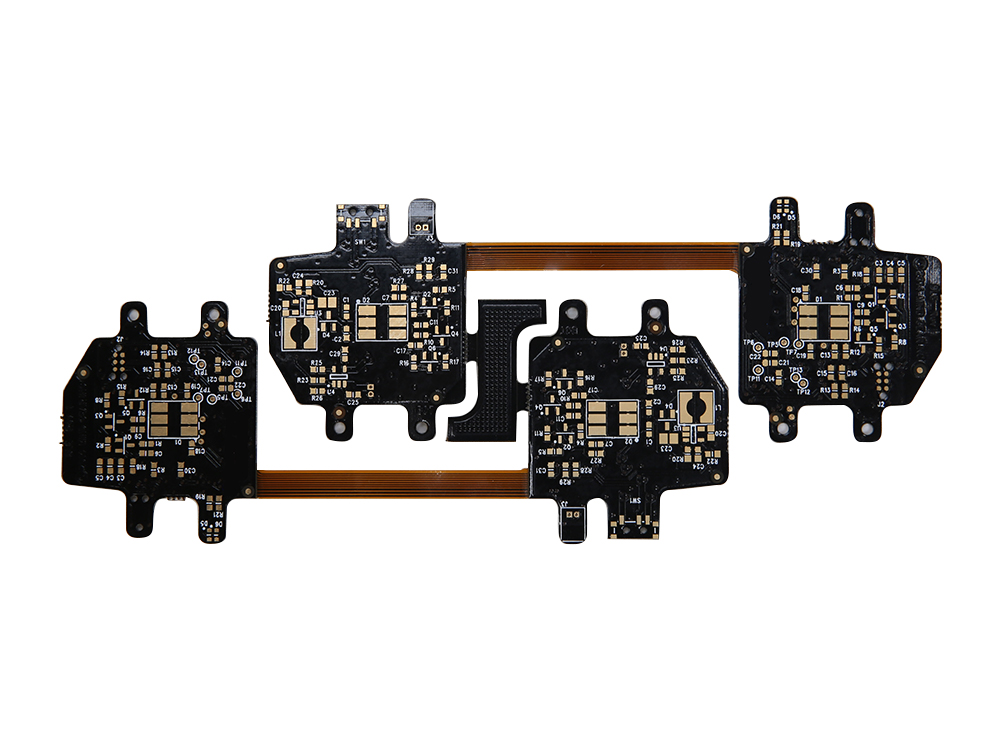

Flex and Rigid-flex PCB

Flex and rigid-flex circuits have found wide use in electronics packaging. Flex boards are so useful in part because they can be made to fit where the smallest rigid boards can’t. SCSPCB offers a variety of solutions including Single-sided Flex, Double-sided Flex Multilayer Flex and Rigid-flex. We utilize advanced technologies and our experience to create rigid-flex circuit boards of the best quality.Our advanced manufacturing facility safeguards that the quality of our products surpasses your expectations.

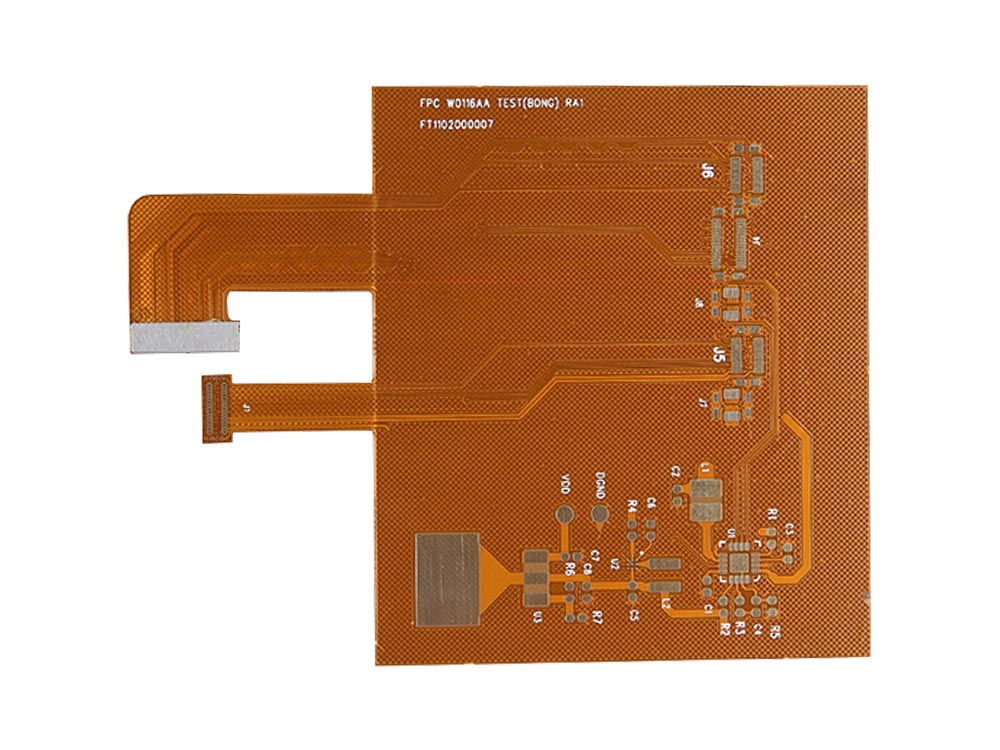

FPC Product

Share this product

Technical Capabilities

| Material Selection | Process Capabilities and Tolerances | ||

| Polyimide | 0.0005″(12 um), 0.001(2 um), | Minimum Trace/Space | 0.0015″/.002(0.33oz.) 0.002″/.0025(0.5oz.) 0.003″/.0035(1oz.) |

| Thickness | 0.002″(50 um), 0.003″(75 um), 0.005″(125 um) |

Minimum Via Hole Diameter (before plating ) |

0.006″ (NC Drill) 0.002″ (UV Laser) |

| Copper (thickness) | 0.25 oz.(9 um), 0.33 oz.(12 um), 0.5 oz.(17 um), 1 oz.(35 um), 2 oz.(70 um) | Minimum Blind Via Diameter (before plating) |

0.004″ (UV Laser) |

| Copper Foils (rolled-annealed) |

Polyimide,Polyester, LPI (liquid photo imageable), PIC(photo imageable cover coat) |

Trace to Edge Distance | 0.O10″ ( NC Route ) 0.008″ (Die Punch) 0.001″ (UV Laser) |

| Stiffeners | FR-4, Polyimide, Metal, or customer supplied | Trace to Edge Tolerance | 0.O05″ ( NC Route ) 0.003″ (Die Punch) O.OO1″ (UV Laser) |

| Thermo-bond Adhesives |

Acrylic, Phenolic Butyral, Modified I Epoxy |

Cover Layer Aperture Positional Tolerance |

O.O05″ (Cover Film) 0.O02″ (LPI and PIC) O.OO1″ (Laser Ablation) |

| Surface Finishes | Solder (hot air leveling or tin/lead plating), Electrolytic Soft BondableGold, Hard Gold, ENIG (electrolessnickel immersion gold), Entek 106A,& Immersion Tin |

Download Details